Fahrion GmbH - Anodized printing

Sub-anodized printing (anodized sub-printing) is a special printing process that is only used for anodized aluminium. The special feature: The ink is not printed onto the material to be printed, but into the porous surface of the aluminum and sealed within it. This results in a print that is smudge- and scratch-resistant and resistant to oil and thinner. Even finger perspiration cannot harm the print for years. Due to these advantages, sub-anodized printing is often used for front panels where the print must not come off even with constant use. Or for medical devices that have to be regularly sterilized and cleaned with aggressive media.

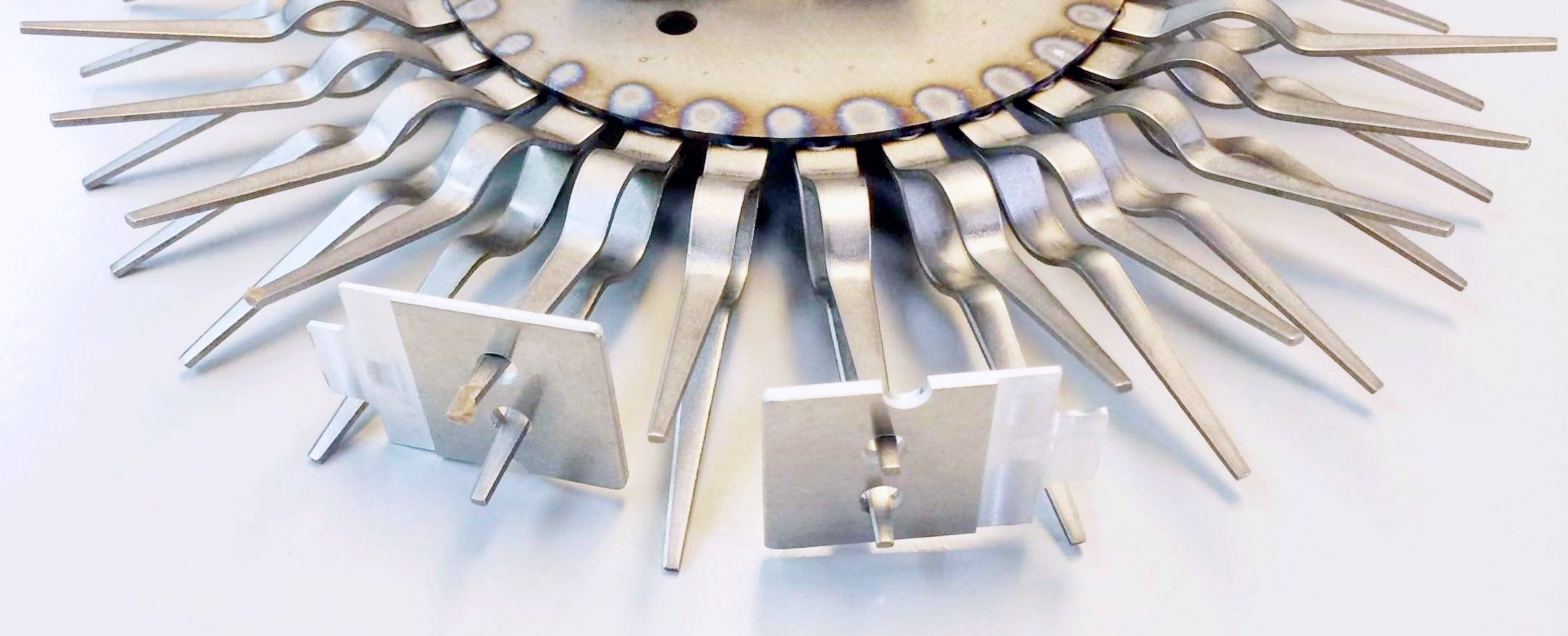

Galvanizing

Galvanizing

Type plates benefit from sub-anodized printing as it is oil and thinner resistant. When printing on aluminum, you can easily test whether it is printed in sub-anodized printing by running your fingernail over the print. If you feel the print slightly raised, it is not sub-anodized printing; if you do not feel any elevation, it is sub-anodized printing. Under-anodizing printing is carried out by interrupting the anodizing process and printing onto the still uncompacted aluminium surface with a special under-anodizing printing ink using a screen printing or digital printing process. The ink is then absorbed into the still open pores of the anodized layer.

Sample business card with anodized printing

Sample business card with anodized printing

The aluminium is then anodized (sealed), i.e. a very thin anodized layer is created that encloses the paint particles. In simple terms, this layer is so thin that it is transparent. The excess ink must then be washed off. The sub-eloxal print is finished!

Another advantage: as the ink hardly runs when printing on the porous surface structure, even the smallest fonts can be printed with sharp edges in sub-anodized printing.

Despite all the advantages, there are also some limitations for sub-eloxal printing:

The special sub-eloxal printing inks cannot be easily mixed like normal screen printing inks. Therefore, you are limited to a few color shades. Company logos that use RAL, HKS or Pantone colors cannot usually be printed color-correct in sub-anodized printing. However, it is possible to print the normal lettering on the front panel in sub-anodized printing and only the company logo in the correct colour in normal screen printing. This allows the advantages of both printing processes to be combined.

The color saturation of the printed colors depends on the anodized layer thickness, the pore geometry, the aluminum alloy used, and much more. All these parameters can never be kept absolutely constant. This can lead to slight fluctuations in color saturation.

If a print goes wrong, the print cannot simply be washed off the front plate and printed again. As the ink quickly soaks into the open pores, the front plate or the sign must be stripped and anodized again. This is particularly problematic for individual pieces or small series (less than 10 pieces), as it is often not possible to achieve an optimum surface when pickling and anodizing again.

As the pores of the anodized surface close by themselves over time, the under-anodized printing must be carried out shortly after anodizing. The still uncompacted anodized surface is very sensitive to contamination of all kinds (dust, finger grease, etc.).

It is therefore a great advantage that Fahrion GmbH can offer anodizing and printing from a single source.

Sub-anodizing printing is only slightly more expensive than normal screen printing for front panels that are individually piece-anodized anyway. This is because essentially only the sequence of processing changes: the anodizing process is interrupted, then the panels are printed and finally they are anodized. The additional work is limited to the additional handling and the necessary cleaning of the sub-anodized print. For front panels that are already anodized, however, the under-anodized printing is somewhat more expensive, as these panels first have to be stripped, re-anodized and compacted. In addition, in this case it must first be tested whether the already anodized front panels are suitable for stripping and anodizing again.

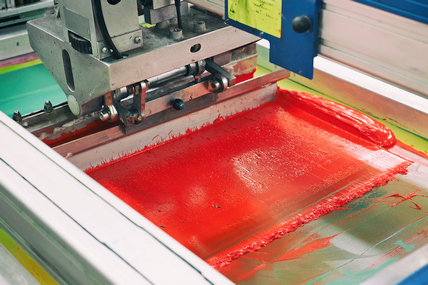

Screen printing

Screen printing

Your contacts:

Olga Herb

Order processing:

E-Mail: info@fahrion-gmbh.de

Telefon: +49 (0) 71 41 / 26 45-36

Fax: +49 (0) 71 41 / 26 45-15

Josua Sinka

Order processing:

E-Mail: info@fahrion-gmbh.de

Telefon: +49 (0) 71 41 / 26 45-37

Fax: +49 (0) 71 41 / 26 45-15

Buchhaltung

Buchhaltung

E-Mail: buchhaltung@fahrion-gmbh.de

Telefon: +49 (0) 71 41 / 2645-24

Fax: +49 (0) 71 41 / 26 45-15