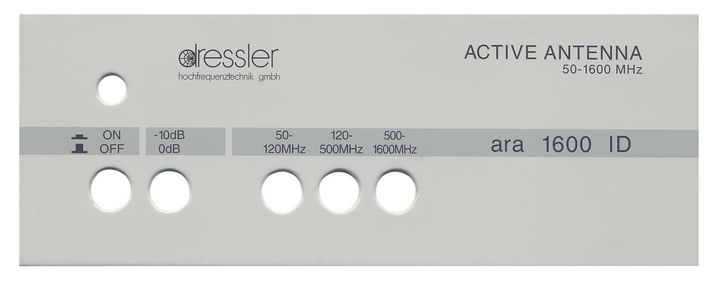

FAHRION GMBH - FRONT PANELS

Front panels are the business cards of your electronics. Your expensive electronics are hidden behind this small piece of sheet metal. We specialize in making your product look as high-quality and as good as possible. That's why we focus on high quality and delivery reliability at a fair cost.

As a front panel manufacturer, we offer you ready-to-install, customized front panels. Our complete service includes everything from mechanical processing to surface finishing and printing. This enables us to guarantee flexibility, short delivery times and competitive prices.

As the front panels are often the last to be designed, we are aware of how urgently they are needed. We do everything we can every day to ensure that your ordered front panels arrive on time so that you can meet your trade fair or delivery deadline.

Aluminium - front panel

Aluminium - front panel

Trumpf TruPunch 3000

Trumpf TruPunch 3000

Our modern CNC punching and nibbling technology enables us to produce both small batches and larger quantities cost-effectively. Thanks to MultiShear® technology, we also guarantee precise and nibble-free processing of the outer edges of your front panels. Thanks to our extensive tool library of over 400 punching tools, additional tool costs are the exception rather than the rule at Fahrion GmbH. We not only have standard tools, but also a large number of special tools for specific applications such as Sub-D, Double-D, HDMI, USB and various display cut-outs. In most cases, this enables us to punch the complete front panel at low cost. Only cut-outs that cannot be punched are milled on our modern Datron® milling machines to guarantee you the highest precision and quality.

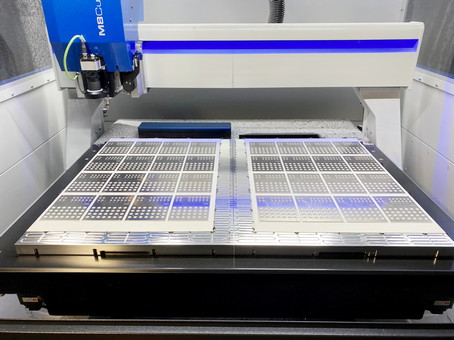

CNC- Fräsmaschine

CNC- Fräsmaschine

The vacuum clamping technology of our modern CNC milling machines enables us to mill many front panels simultaneously. This makes the milling of aluminum front panels an increasingly attractive alternative to stamped front panels in terms of price. During milling, pockets, chamfers, threads or even countersinks can be milled in a single clamping operation.

When designing your front panel, make sure that the corner radii are not too small. A corner radius of 1 mm is ideal. If it has to be smaller, time-consuming re-milling with a very thin 1 mm cutter is required, which drives up the costs. Our smallest corner radii for milling are 0.5mm.

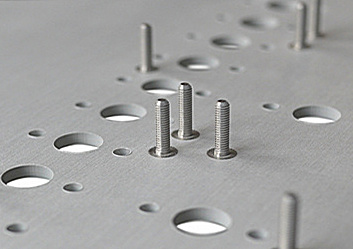

For the rear mounting of PCBs or other mechanical components, Fahrion GmbH offers the option of attaching weld studs or press-fit studs (blind hole threaded studs). Both options enable a fixed mechanical connection that remains invisible on the printed front side of your front panel. The welding studs are precisely positioned and fastened using our CNC welding system.

We also ensure that any weld beard is removed without leaving any residue after the welding process. In addition, we subject every single stud to a thorough mechanical test. For specific requirements, we offer press-fit studs or press-fit bushes (with internal thread) that are pressed into a milled blind hole. While this method can be slightly more costly than the welded version, it offers greater and more reliable mechanical strength.

If the front panel is then to be anodized, we only use aluminium bolts. These bolts are available in many different versions (M3 to M6) and lengths (6, 8, 10, 12, 16 mm). Let us advise you.

Front panel with press-in bolt

Front panel with press-in bolt

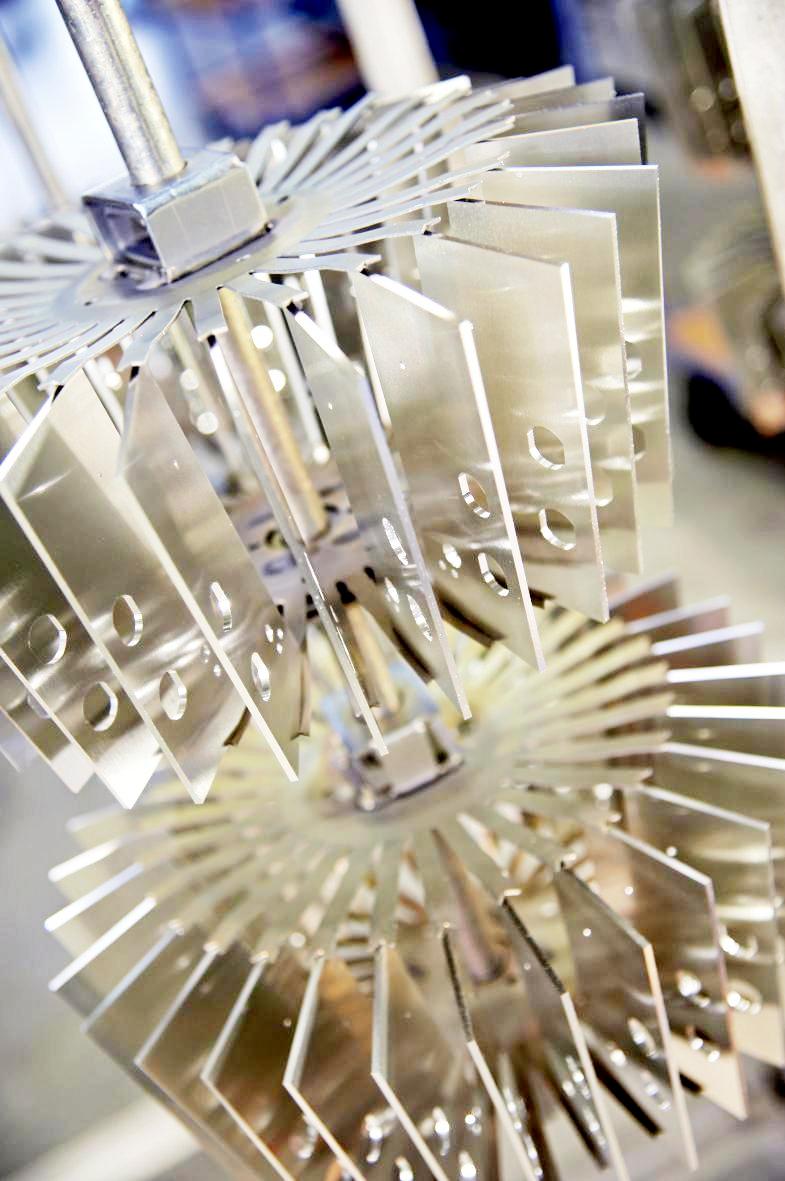

Galvanic (anodizing of front panels)

Galvanic (anodizing of front panels)

Our in-house electroplating and screen printing department enables us to print all anodized front panels cost-effectively using sub-anodized printing (anodized underprinting). This process produces an absolutely smudge- and scratch-resistant, oil- and thinner-resistant print.

This is made possible by the fact that the ink is not simply printed onto the surface of the front panel, but is printed deep into the uncompacted, open pores of the anodized layer. A thin and transparent anodized layer (saeling) seals the ink into the anodized pores. This protects the print from abrasion (e.g. caused by aggressive finger perspiration) or harsh cleaning agents or disinfectants and keeps it protected for years.

We use special printing inks for under-anodized printing, which are applied using the screen printing process. We offer both silver matt (E6/EV1) and black (E6/C35) anodized coatings. Both anodized surfaces are very suitable for scratch-resistant yet elegant front panels. When printing the aluminum front panels using the anodized underprinting process, HKS, RAL or Pantone® colors can only be reproduced approximately due to the special colors. We would be happy to advise you on the possibilities and best options for your project.

As an alternative to anodizing, we offer painting of the front panels in various RAL colors in our in-house paint shop. Painted front panels offer the advantage of a uniform appearance in a rack, whereas anodized front panels from different batches may exhibit slight variations, e.g. in gloss level. Please note, however, that painted front panels are more susceptible to scratches than anodized ones. To counteract this, we offer an optional protective coating with clear lacquer. This lacquer coating protects both the lacquer coating and the print from scratches and finger sweat.

Spray-painted front panel

Spray-painted front panel

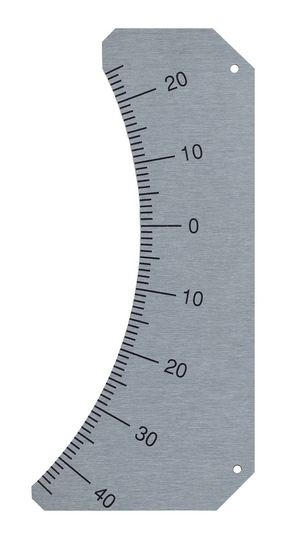

Scales with under anodized printing

Scales with under anodized printing

We manufacture scales, rulers and round scales with high precision on our CNC milling machines. The scales are printed using sub-anodized printing, which makes the lettering extremely scratch-resistant and thinner-resistant. Only an engraved scale is even more robust, but also significantly more expensive, as engraving takes considerably longer than the printing process. Put it to the test! Request our Untereloxal sample business card and test the scratch resistance of the print. You will see that an engraved scale is only necessary in the rarest of cases.

Email us your drawing or DXF file and we will provide you with a staggered offer for your individual scale.

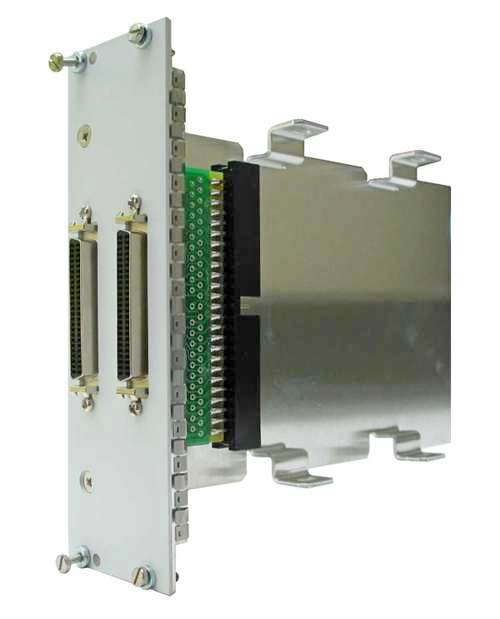

front panel with assembly

front panel with assembly

As a front panel manufacturer, we are happy to process aluminum front panels supplied by enclosure manufacturers. Our services include milling according to your drawing, painting, powder coating or anodizing according to your wishes and printing according to your template. Take advantage of our many years of experience in the production of profile front panels. On request, we can fit attachments, screws, etc. to the front panel. The finished product is individually packaged and labeled according to your wishes.

We recommend that you design your front panel in a neutral program that offers DXF export (or similar). This means you are not tied to a specific manufacturer and can then provide your front panel supplier with a DXF file for production. This avoids costs and errors. It is better not to use special front panel designers that do not allow the data to be exported. We recommend common vector graphics programs such as Adobe Illustrator or CorelDraw for designing the printing.

We look forward to receiving your inquiry and will be happy to provide you with a quote with graduated prices.

Contact persons for front panels

Olga Herb

Customer service and consulting

Mail: frontplatten@fahrion-gmbh.de

Phone: +49 (0) 71 41 / 26 45-35

Fax: +49 (0) 71 41 / 26 45-15

Tanja Wenzl

Customer service and consulting

Mail: frontplatten@fahrion-gmbh.de

Phone: +49 (0) 71 41 / 26 45-35

Fax: +49 (0) 71 41 / 26 45-15

ACCOUNTING

Accounting

Mail: buchhaltung@fahrion-gmbh.de

Phone: +49 (0) 71 41 / 26 45-24

Fax: +49 (0) 71 41 / 26 45-15