FAHRION GMBH - SHEET METAL PROCESSING

Sheet metal processing should be precise, uncomplicated and above all fast. We are committed to offering and executing your order at short notice. We offer a wide range of services at the highest level and quality. We distinguish ourselves through many years of know-how, the most modern technology and a qualitatively extremely reliable production.

We take care of your project from consulting and planning to programming, manufacturing and shipping. With Fahrion GmbH as your partner in sheet metal processing, you get everything from a single source. Reasonably priced and fast.

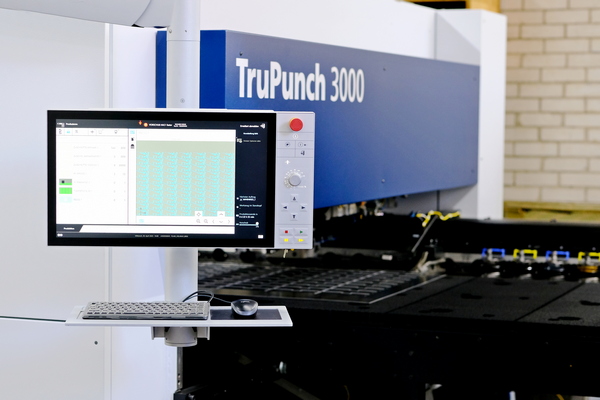

Trumpf TruPunch 3000

Trumpf TruPunch 3000

CNC punching technology

CNC punching technology

Our Trumpf TruPunch 3000 punching/nibbling machine offers you new technological advantages:

- Nibble-free outer edges thanks to multishear tool technology.

- Deburring on the machine (roller deburring)

- machine-formed countersinks

- Scratch-free backsides thanks to lowerable die

- increased speed

- faster automatic tool change

- faster rotary head

- data transfer of common CAD programs (dxf, other formats on request).

For the rear mounting of PCBs or other mechanical components, Fahrion GmbH offers the option of attaching weld studs or press-fit studs (blind hole threaded studs). Both options enable a fixed mechanical connection that remains invisible on the printed front side of your front panel. The welding studs are precisely positioned and fastened using our CNC welding system.

We also ensure that any welding beard is removed without leaving any residue after the welding process. We also subject each individual stud to a thorough mechanical test. For specific requirements, we offer press-fit studs or press-fit bushes (with internal thread) that are pressed into a milled blind hole. While this method can be slightly more costly than the welded option, it offers greater and more reliable mechanical strength.

CNC stud welding

CNC stud welding

CNC milling

CNC milling

If punching and nibbling marks on the inside edges of cut-outs are disturbing, these can be reworked on our CNC milling machines. Please note that this results in a corner radius of R=1mm. If necessary, this radius can be reduced to R=0.5mm, but this is associated with additional costs, as we have to rework all corners with a 1mm milling cutter.

Chamfers, bed or pocket milling, countersinks, threads, etc. are also technically feasible on the milling machine. Let us advise you.

This is what we offer you:

Mechanics

- CNC - Punching

- CNC - Milling

- CNC - stud welding

- Press-in stud

- Profile machining

- Simple sheet bending

Surface

- Anodizing

- Painting in RAL colors

- Chromated/anodized Surfaces

- Powder coating

Marking

- Screen printing

- Sub-eloxal printing

- Typesetting and film production

- Film lettering

- Engraving

We can't go for that : Housing production/ multiple edging/ typical laser parts (free-form contours).

Contact person

Olga Herb

Customer service and advice

Mail: frontplatten@fahrion-gmbh.de

Phone: +49 (0) 71 41 / 26 45-35

Fax: +49 (0) 71 41 / 26 45-15

Josua Sinka

Customer service and advice

Mail: frontplatten@fahrion-gmbh.de

Phone: +49 (0) 71 41 / 26 45-35

Fax: +49 (0) 71 41 / 26 45-15

Buchhaltung

Buchhaltung

E-Mail: buchhaltung@fahrion-gmbh.de

Telefon: +49 (0) 71 41 / 26 45-24

Fax: +49 (0) 71 41 / 26 45-15