Fahrion GmbH - LASER ENGRAVING

Laser marking is an important part of modern marking technologies today. It is not the only marking option that makes all marking tasks easier and cheaper, but rather another tool with advantages and disadvantages. Laser marking has particular strengths when single-color marking is sufficient and when changing print motifs are required, such as for consecutive numbering. In order to achieve good contrast and legibility, it is necessary for the lasered material to undergo a clear colour change (such as when lasering wood), or if a different coloured top layer is lasered away, such as with coloured anodized aluminium.

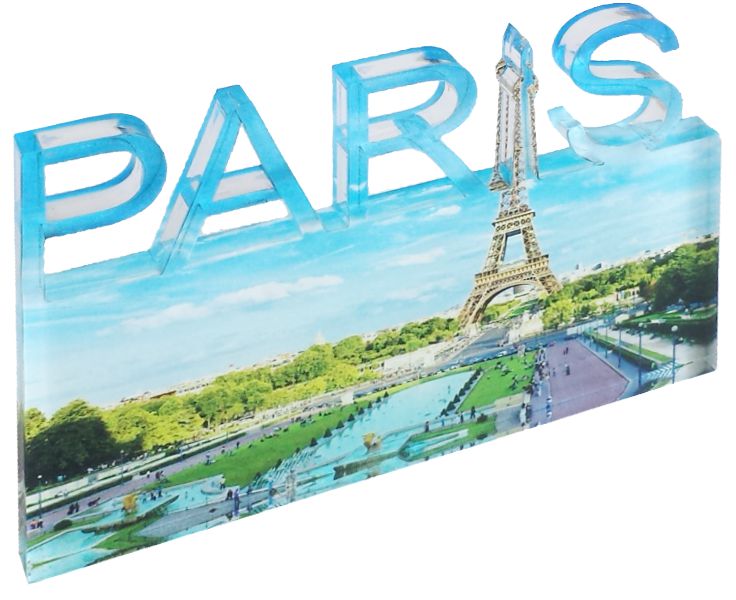

Uniquely shaped acrylic glass sign

Uniquely shaped acrylic glass sign

- The advantages include:

- Simple serial numbering

- Engraving of geometrically challenging surfaces (e.g. curved or difficult-to-access surfaces)

- Engraving and cutting in a single process

- Engraving without complex fixtures

- Scratch-proof (depending on the engraving depth)

- No chemical additives required

- The greatest disadvantages:

- Does not tend to show the best contrast

- Only single colour markings (*)

- Engraved organic materials have a distinctive smell (e.g. wood has a burnt smell that dissipates with time)

- Not all materials can be processed

- Often only suitable for functional marking (labels)

- Results depend on the material being processed (sample required)

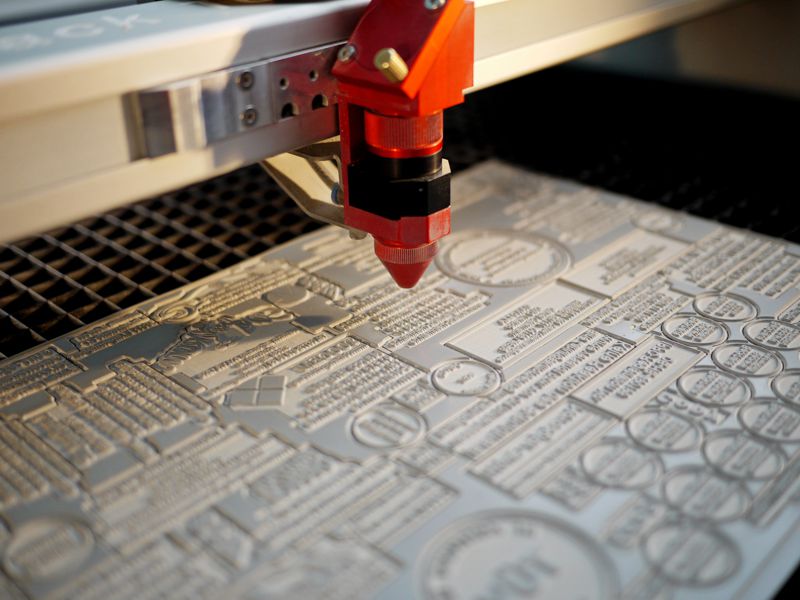

There are two basic laser engraving methods for marking materials:

1.) Due to the highly concentrated beam of light the structure of the material surface is visibly altered (e.g. wood is branded, cast acrylic glass loses its transparency and turns a milky white)

2.) Removal of a thin layer of the material surface brings to the fore the different coloured surface below (e.g. when marking anodised aluminium or coated surfaces).

Laser engraving rubber

Laser engraving rubber

We engrave and cut using several 120-watt CO2 flatbed lasers. The relatively high laser power enables us to process thicker materials or work at a faster speed with thin materials. The CO2 laser can be used to cut and engrave materials such as wood, acrylic glass, leather, and many plastics. Aluminum can only be engraved, not cut. The working area is approximately 800 mm x 500 mm and the maximum workpiece height is 185 mm. This means that there are virtually no limits to larger cutting tasks or panel production.

With our fiber laser, we engrave metals and mark leather, metals, paper, plastics, and textiles at lightning speed. Since only the laser beam is deflected with this type of laser, very fast marking is possible.

Due to the many different marking tasks, materials and requirements, it is difficult for us to define fixed rules on what is possible and what is not. Please give us a call or send an email with your requirements and together we will find the perfect solution. Thanks to the wide range of methods available to us, we offer you comprehensive advice on all aspects of marking.

As manufacturer of front panels with the possibilities of our sheet metal processing occur in combination with the laser marking interesting manufacturing process. So we can, for example, bylabeling of rating plates the invariant areas in screen printing and laser engraving the variable fields only. Then the high-quality screen printing, which also enables company logos in multiple colors, combined with the flexibility of laser marking.

Laser cut and painted wood

Laser cut and painted wood

(*) With certain types of metal it is possible to achieve annealing colours by carefully regulating the amount of energy delivered to the material surface by the laser. The end result may be multi-coloured laser engravings. How- ever, the colours will not be rich in contrast and it is not possible to reproduce colour systems (RAL, HKS, Pantone).

Further information about laser engraving can be found under:

http://de.wikipedia.org/wiki/Laserbeschriftung

Contact persons for laser engraving

CHRISTOPHER PACH

Department Manager

E-Mail: werbeartikel@fahrion-gmbh.de

Telefon: +49 (0) 71 41 / 26 45-0

Fax: +49 (0) 71 41 / 26 45-15

ACCOUNTING

Accounting

E-Mail: buchhaltung@fahrion-gmbh.de

Telefon: +49 (0) 71 41 / 26 45-24

Fax: +49 (0) 71 41 / 26 45-15