FAHRION GMBH - ANODISED NAME PLATES

Name plates are long-lasting information carriers. They are often exposed to adverse conditions such as abrasion, oil and harsh cleaning fluids. For this reason, we largely produce nameplates using sub-anodized printing. This printing process is absolutely abrasion-, oil- and thinner-resistant, as the ink particles do not sit on the surface of the sign, but are anchored in the material. You can find more details about sub-anodized printing on our sub-anodized printing page.

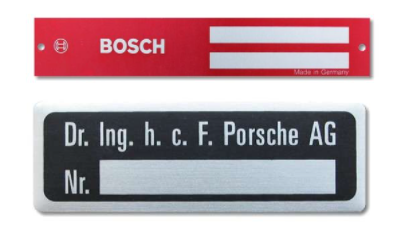

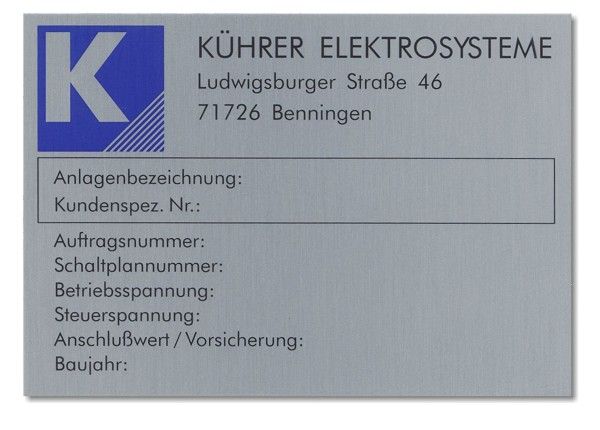

Anodised name plates in sub-eloxal printing

Anodised name plates in sub-eloxal printing

The type plates are attached using screws/rivets or a self-adhesive film. The latter is only recommended for smooth and clean surfaces. Type plates are usually custom-made, so that any size and shape can be produced according to your wishes. Company logos can be realized in all available sub-anodized printing colors. To save possible tool costs, please let us know your desired size and we will look for a suitable tool in our extensive tool library.

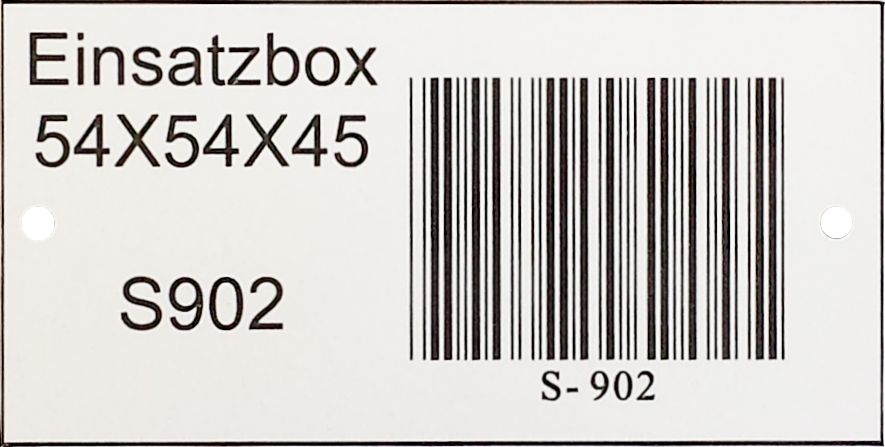

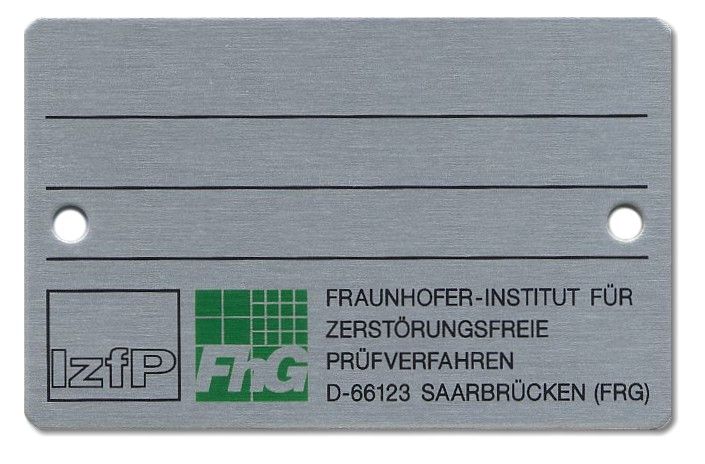

Aluminum nameplate

Aluminum nameplate

Our in-house electroplating facility in conjunction with the screen printing department enables us to produce front panels and nameplates using sub-anodized printing at no extra charge. For larger quantities, we produce the type plates or machine plates economically and quickly by printing multiple plates simultaneously.

Subsequent variable labeling is carried out either by laser engraving, CNC engraving or by the customer using punch numbers. As the type plates bend when inscribed with punch numbers, they should not be attached using adhesive in this case. We can carry out consecutive numbering for you using laser engraving. In this case, the labeling fields must be printed in black. The laser then engraves away the black layer and the numbering appears in silver. We are happy to engrave your nameplates on demand, which means the nameplate blanks are stored with us and you call off the engraving individually.

Type plate self-adhesive

Type plate self-adhesive

Sample business card in sub-eloxal printing

Sample business card in sub-eloxal printing

Ask for our sample business card printed using the sub-anodized printing process. You can use it to test the advantages of sub-anodized printing, such as absolute scratch resistance and chemical resistance.

Contact persons for Name plates

Olga Herb

Customer service and consulting

Mail: frontplatten@fahrion-gmbh.de

Phone: +49 (0) 71 41 / 26 45-35

Fax: +49 (0) 71 41 / 26 45-15

Josua Sinka

Customer service and consulting

Mail: frontplatten@fahrion-gmbh.de

Phone: +49 (0) 71 41 / 26 45-35

Fax: +49 (0) 71 41 / 26 45-15

ACCOUNTING

Accounting

E-Mail: buchhaltung@fahrion-gmbh.de

Telefon: +49 (0) 71 41 / 26 45-24

Fax: +49 (0) 71 41 / 26 45-15